The strength of Grade 630 Stainless steel

Grade 630 Stainless steel, also known as 17-4PH, is one of most commonly used of the high strength Stainless steels. It is a precipitation hardened grade, and belongs to the 600 series Stainless steels, known as the Martensitics Precipitation Hardening Alloys.

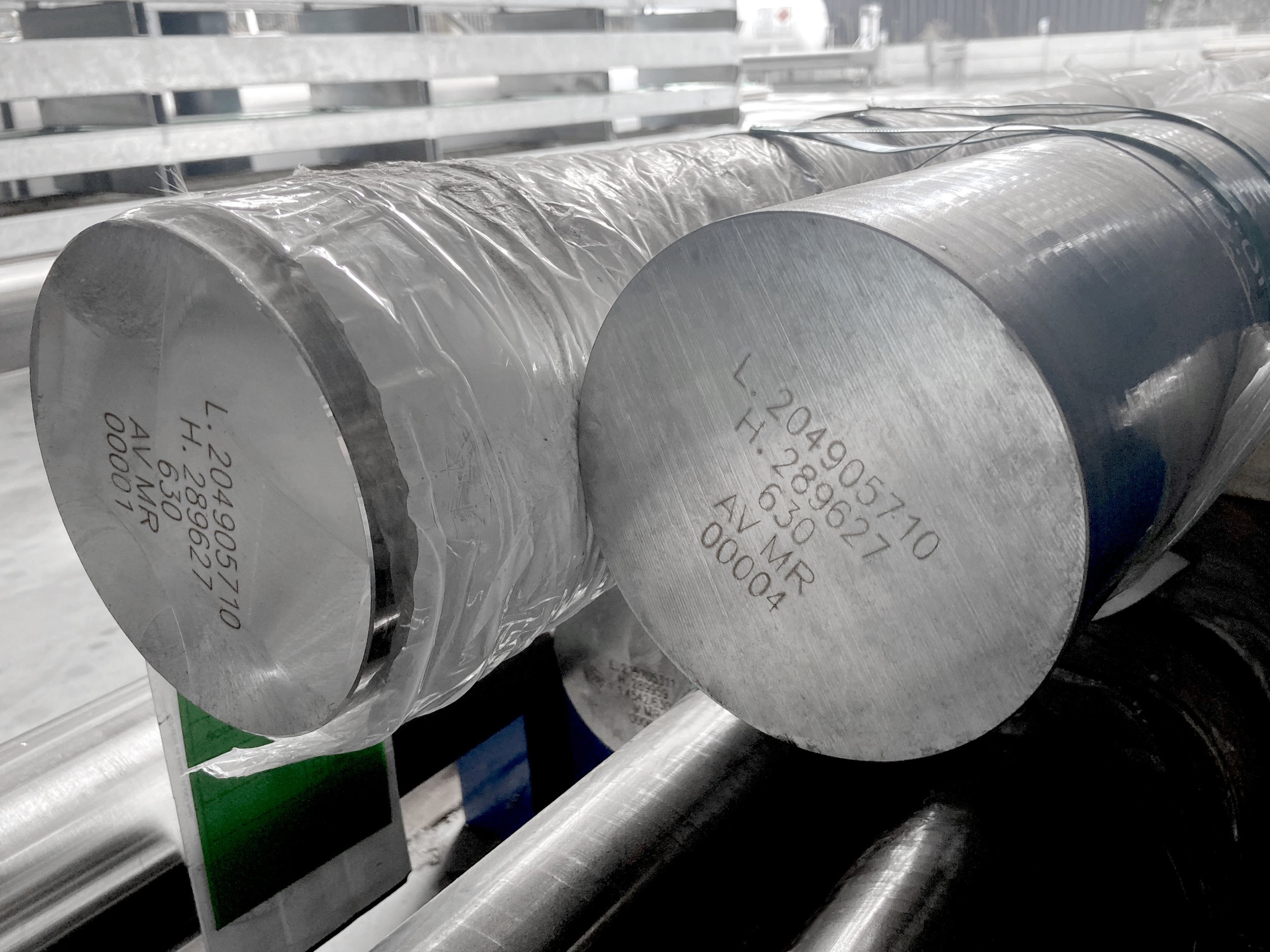

Stirlings stocks and supplies Grade 630 in Round Bar form; it is a vital addition to many projects due to its superior strength and durability. It is commonly specified for Oil & Gas and Aerospace requirements.

Keep reading for an exploration of the composition and properties of Grade 630 Stainless steel, as well as its applications and our stock at Stirlings.

Composition & Properties

Stirlings stocks H1150D Grade 630 Bar - the Stainless is hardened twice (2 x 620°C for 4 hours).

The “17-4PH” name refers to 17% Chromium, 4% Nickel Precipitation Hardening.

Type 630 Stainless steel is often produced to ASTM A564.

Precipitation hardening Stainless steels provide an optimum combination of the properties of martensitic and austenitic grades; like martensitic grades, they are known for their ability to gain high strength through heat treatment and they also have the corrosion resistance of a particular range of austenitic Stainless steel. The high tensile strengths of precipitation hardening Stainless steels come after a heat treatment process that leads to precipitation hardening of finely sized and dispersed carbides within a martensitic or austenitic matrix. This mechanism is also often seen in certain aluminium alloys as well as some nickel based alloys.

Properties

Corrosion Resistance

Precipitation hardening Stainless steels have moderate to good corrosion resistance in a range of environments. They have corrosion resistance is similar to that found in Grade 304 Stainless steel. Grade 630 is not suitable for warm chloride environments without adequate protection e.g. Anodic / cathodic. It is highly resistant to stress corrosion cracking, and better stress corrosion cracking resistance comes with higher ageing temperatures. As it is also resistant to sulphide induced SCC, it complies with NACE MR0175, allowing its use in upstream oil and gas applications.

Heat Resistance

Grade 630 has good oxidation resistance in the temperature range from -29°C to 343°C, though not like 304 and 316 which have a much wider operating band. In order to avoid reduction in mechanical properties, it should not be used over its precipitation hardening temperature.

Extended exposure between 370-500°C can cause embrittlement issues, resulting in loss of ductility and toughness at room temperature.

Strength

Grade 630 Stainless is known for its exceptional yield and tensile strength, close to doubling that austenitic and even higher than super duplex Stainless steel depending on its condition.

Being a hardenable alloy, there are several conditions it can be supplied in; from an annealed state, to the strongest H900 condition which gives at least 1310MPa tensile strength. For context, 316 reaches around 550MPa, while grade 2507 gives around 800MPa – a huge difference. Hardness is also very high – at least 40 HRC.

The tradeoff is that elongation is very low, around 10%, a weakness for many applications. Hence it is common to harden at higher temperatures, up to 620°C, which while reducing strength slightly, improves toughness considerably.

Weldability

Precipitation hardening steels can be readily welded using procedures similar to those used for the 300 series of Stainless steels. Grade 630 can be successfully welded without preheating. Heat treating after welding can be used to give the weld metal the same properties as for the parent metal. The recommended grade of filler rods for welding Grade 630 (17-4 PH) is 17-7 PH. This is a significant advantage to other high strength stainless grades like 431.

Applications

Due to the high strength Grade 630 Stainless steel, most applications are in Oil & Gas, Aerospace and other high-technology industries, applications including:

Valves, gears and other engine components;

High strength propeller and pump shafts;

Turbine blades;

Aircraft and gas turbines;

Moulding dies;

Nuclear reactors and waste casks;

Oil field equipment;

Paper mills;

Chemical processing equipment.

Grade 630 at Stirlings

Stirlings stocks Grade 630 in condition H1150D & most of the range in a centreless ground finish.

The benefit of this condition is high strength – typically around 900 - 1000MPa, with a relatively good elongation of typically +20%.

Well stocked and well priced, Stirlings can advise on suitability for a range of operating conditions and applications, even as a substitute to some grades like 431.

The below image is an extract from a test certificate, showing typical values.

Obtaining Grade 630 Stainless

Need to get your hands on some Grade 630 Round Bar? It’s as easy as checking out our stock here, and requesting a quote here.

If you are after something we don’t carry - don’t stress! With our excellent supply network, we can source it for you.

A rhyme for your time

Looking for Round Bar with high tensile strength? Stirlings has Grade 630 in many a length!

Sources