What is a Fiber Laser, and demonstrating Stirlings' incredible Laser capabilities

A bit about Lasers

A Laser is a device that generates light in the form of a Laser beam. A Laser beam is different from a light beam in that its rays are monochromatic (a single color), coherent (of the same frequency and waveform), and collimated (going in the same direction).

The word laser is an acronym for “Light Amplification by Stimulated Emission of Radiation”.

Lasers are comprised of three main components:

The energy source pumps light into a gain medium.

The gain medium emits light of a specific wavelength when excited by light. (Lasers are typically named after their gain medium. In a CO₂ Laser, the gain medium is CO₂ gas).

The resonator amplifies the optical gain through mirrors that surround the gain medium.

Lasers come in five main forms:

Semi-conductor Lasers (Laser Diodes)

Similar to regular diodes with a positively-negatively (PN) charged junction, but have an intrinsic layer at the PN junction made of materials that create spontaneous emission.

Used in barcode readers, Laser pointers, Laser printers, Laser scanners, and more.

Liquid Lasers (Dye Lasers)

Use an organic dye in liquid form as their gain medium.

Used in Laser medicine, spectroscopy, birthmark removal, and isotope separation.

Solid State Lasers

Use a solid (crystals or glasses) mixed with a rare earth element, typically neodymium, chromium, erbium, thulium, or ytterbium, as their source of optical gain.

Used in material processing, for LIDAR technology as well as various medical applications, including tattoo and hair removal, tissue ablation, and kidney stone removal.

And the two types relevant for our discussion:

Gas Lasers - e.g CO₂ Laser

Laser for which an electric current is sent through a gas to generate light (population inversion).

Used in material processing, holography, spectroscopy, barcode scanning, air pollution measurements, and Laser surgery.

CO₂ Lasers are mainly used for Laser marking, Laser cutting, and Laser welding.

Fiber Lasers

A special type of solid-state Laser that is a category of its own. The gain medium is an optical fiber (silica glass) mixed with a rare-earth element.

Used in material processing (Laser cleaning, texturing, cutting, welding, marking), medicine, and directed energy weapons.

As CO₂ and Fiber Lasers are the most common types utilised in materials processing we will further discuss and compare them in this blog, particularly the details of the Fiber Laser, the most powerful and efficient Laser available for this use.

How does a Fiber Laser work?

Get some in depth knowledge of how Fiber Lasers function with this helpful video; it’ll be quicker than reading!

Fiber Lasers vs CO₂ Lasers

Compared to a CO₂ Laser, a Fiber Laser’s laser beam energy is absorbed more efficiently by the metal surface. Fiber Lasers have around 50% lower operating costs, faster processing speeds, higher precision, and require less maintenance.

CO₂ Lasers

In general, CO₂ Lasers deliver faster initial piercing times, quicker straight-line cutting and a smoother surface finish when cutting materials above 5mm. However, they use significantly more power than Fiber Lasers. A high-power CO₂ Laser and chiller will consume roughly 70kW when operating on maximum power, compared to similarly powered Fiber Laser consuming approximately 18kW.

Fiber Lasers

Fiber Lasers produce an extremely small focal diameter (resulting in intensity up to 100 times higher than a CO₂ system). In addition, they are relatively maintenance-free and have a long service life. As stated, due to the high electrical efficiency of Fiber Lasers, they allow huge cost savings for cutting applications.

As of 2024, engineers and manufacturers have discovered ways to emulate CO₂ Laser effects in Fiber Lasers, thus are achieving better results in thicker materials. This new capability, combined with the other benefits provided by Fiber Lasers, demonstrate a clear superior method in materials cutting.

Stirlings’ Fiber Laser

Stirlings currently has in use a Penta Bolt VII 12025 20kW Fiber Laser in our Bibra Lake, W.A warehouse. As of this time, this is the largest format Laser in Australasia, with the most powerful cutting cability in our industry.

The benefits of Stirlings’ machine are the following:

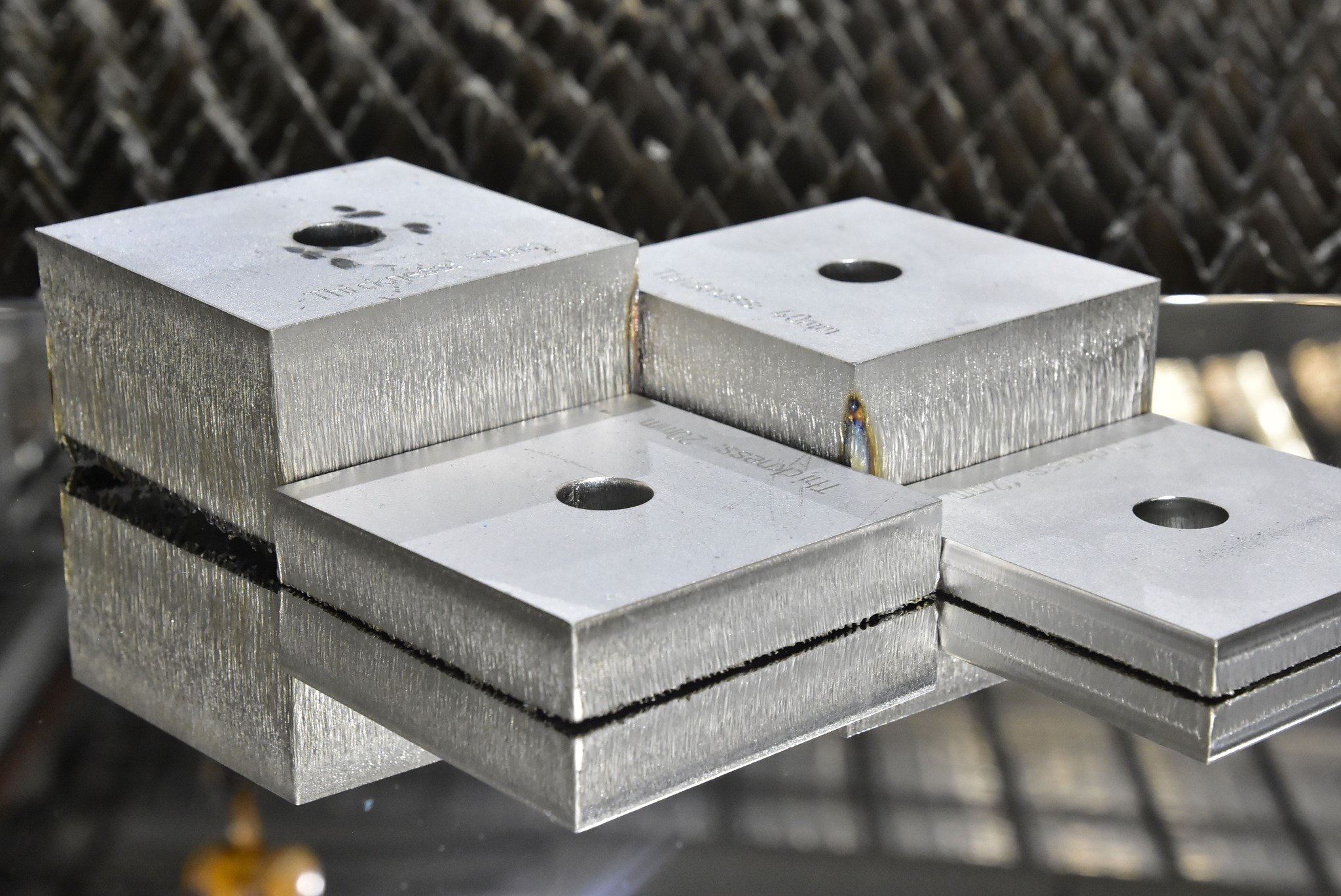

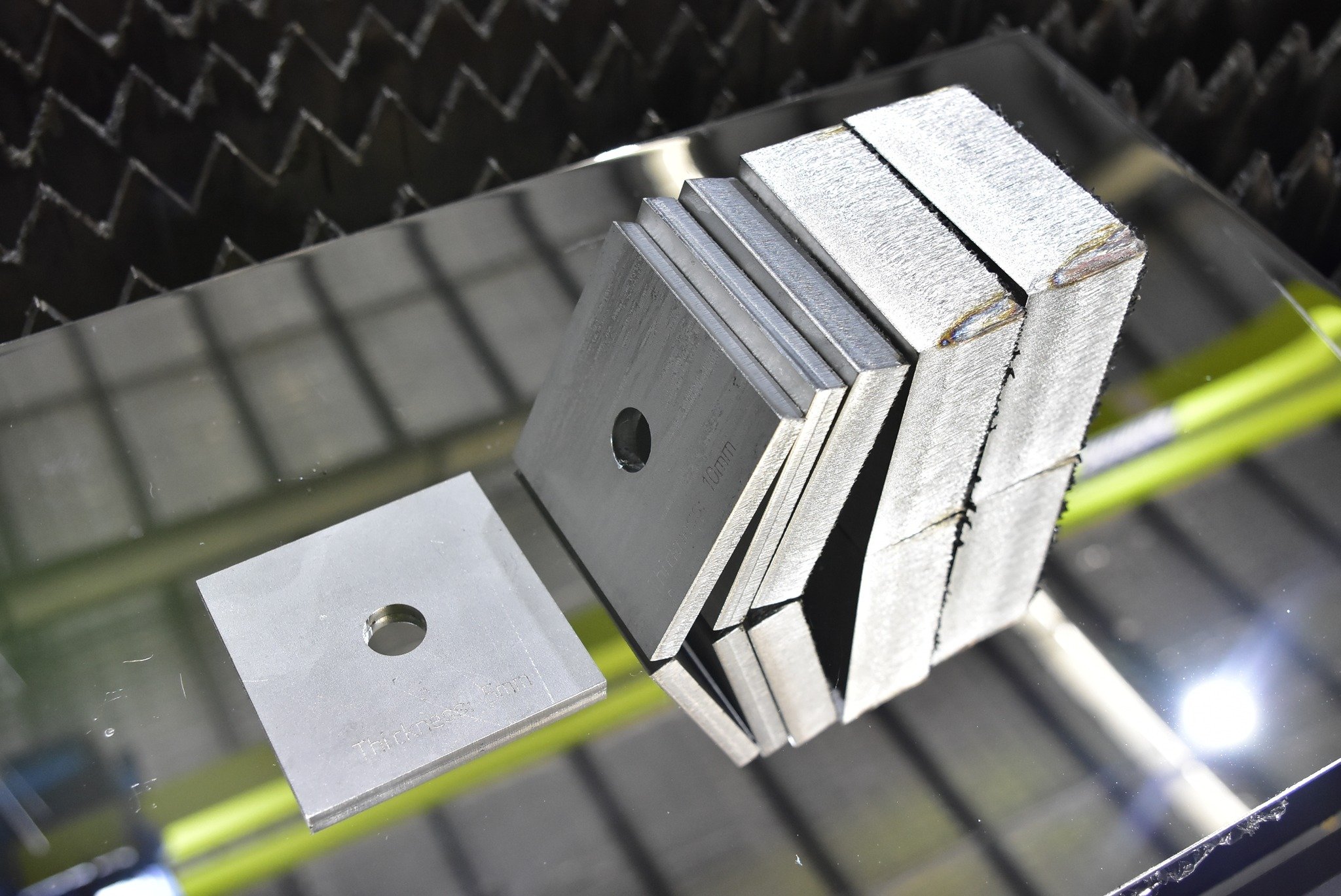

High speed laser cutting to 60mm thickness providing a superior edge compared to incumbent plasma process solutions;

Very small holes throughout range of thicknesses essentially at least half the thickness allowing for consolidation of downstream processes such as drilling;

Minimal dross on bottom edge of cut to 20mm thick reducing post cutting edge clean up;

Cutting plate sizes up to 12,000mm x 2,500mm;

High speed laser etch marking on all parts;

A more eco-friendly option compared to it's CO₂ technology counterparts, with cutting technology that demostrates a high output compared to vastly reduced consumption of power & gas, reducing carbon emissions.

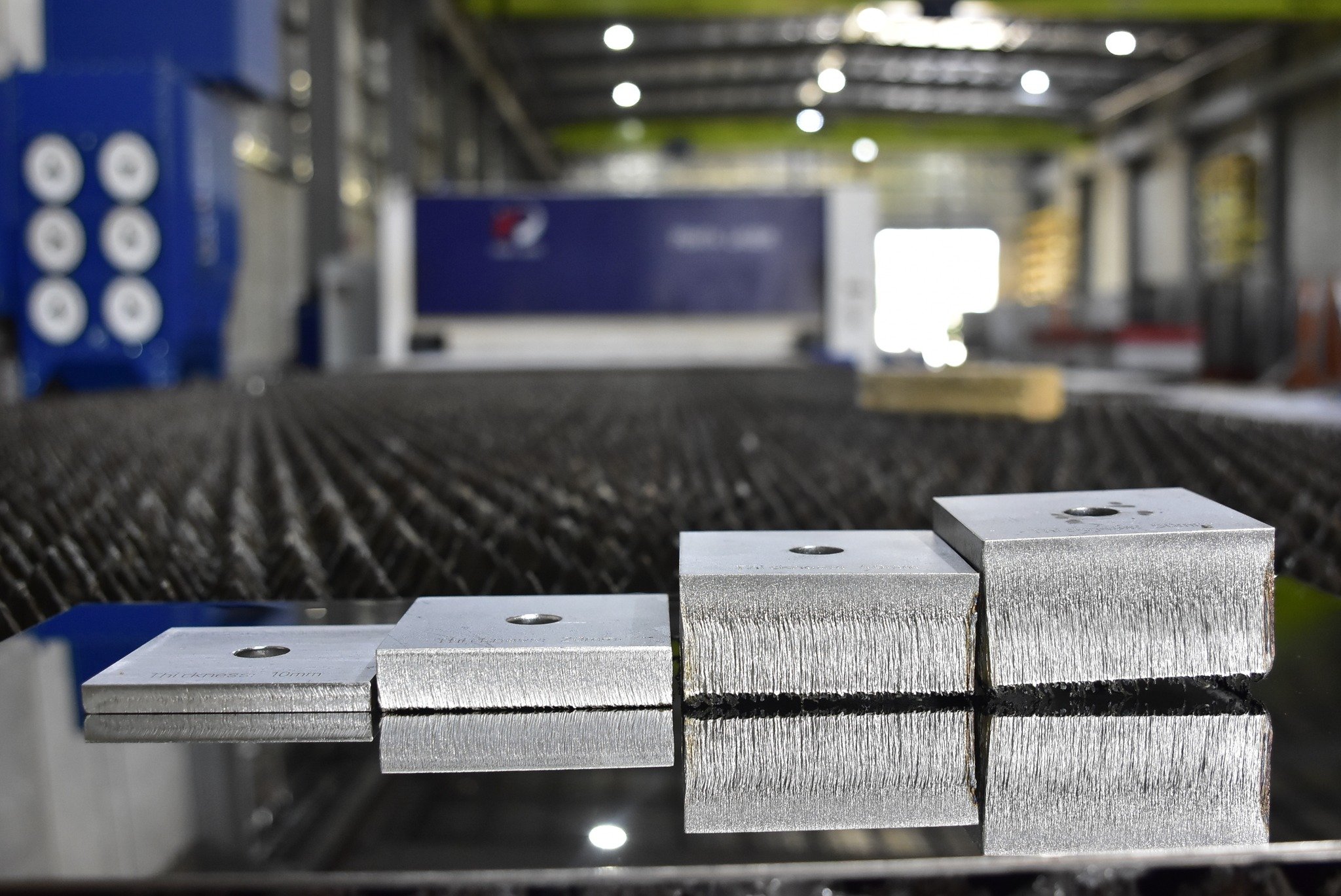

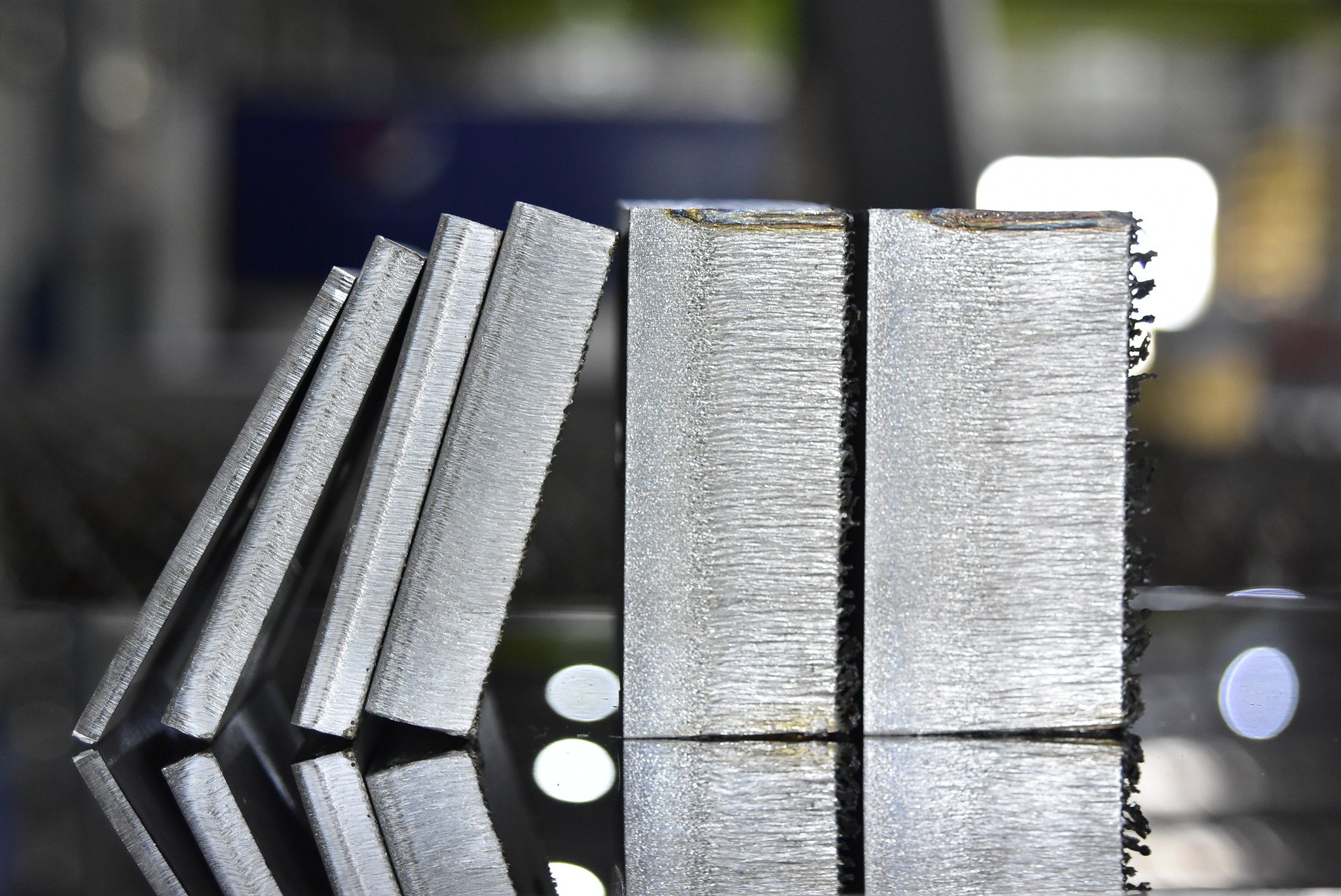

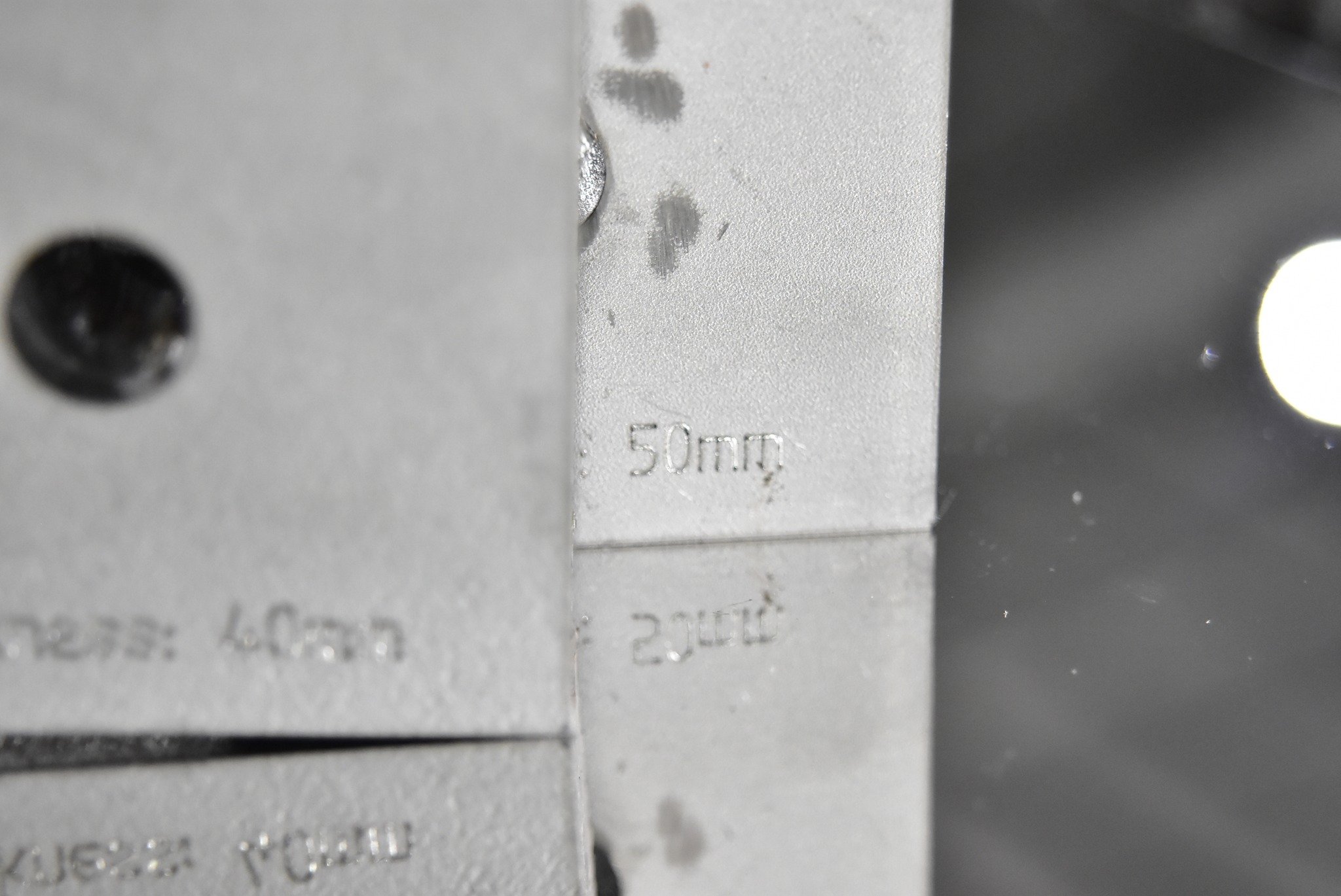

Using the Stirlings’ Penta Bolt 20kW Fiber Laser, we cut all of these sample 100mm x 100mm square pieces with a 10mm diameter hole in thicknesses:

3mm

5mm

6mm

8mm

10mm

12mm

16mm

20mm

25mm

32mm

40mm

50mm

See below a video demonstration:

In addition to our 20kW machine, a new Stirlings Penta Bolt 60kW Fiber Laser will be commissioned May 2024, further extending our already market leading processing capabilities in 'in-house' Laser cutting.

The new 60kW machine will enable us:

Take over from our Plasma cutter on thicker guage materials, while offering a square cut sholder, no visibly detectable kerf and significantly minimising e;

To cut 100mm & even 150mm thick at maximum;

To totally dry cut, so Plates are processed without stains and watermarks, assisting with fabrication and presentation of completed parts;

Speed: the 60kW cuts 2x to 3x faster than even the 20kW in thicknesses 20mm – 50mm, resulting in shorter turn around times to all parts of Australia;

A combined 80kW of cutting capacity, backed by the broadest and deepest stockholding of plate in Stainless steels.

See below a video demonstration:

The Advanced Software System of both machines ensures state-of-the-art Laser cutting capability.

They are both equipped with specialised high-power Laser cutting heads, to ensure continuous operation with efficiency and stability. It also posesses sharp angle cutting and precision cutting technology.

Our Laser services, for you

Our Laser machines are here to provide superior services for you, our customers! Like what you see? Get in touch to get your needs met by our Fiber Lasers.

The addition of our 60kW Laser demonstrates all of the benefits as stated above, as well as significantly lower lead times - allowing us to provide you with the meticulous Stirlings service, faster than ever before!

A rhyme for your time:

Want to use our Fiber Lasers to get a superior cut? Over to our enquiry form you need to strut!

Sources:

https://pentalaser.com.au/product/top-speed-bolt/

https://www.laserax.com/blog/types-lasers

https://www.laserax.com/blog/co2-vs-fiber-lasers

https://eagle-group.eu/en/how-does-a-fiber-laser-work

https://www.southernfabsales.com/blog/co2-laser-vs-fiber-laser