CSL Seqirus

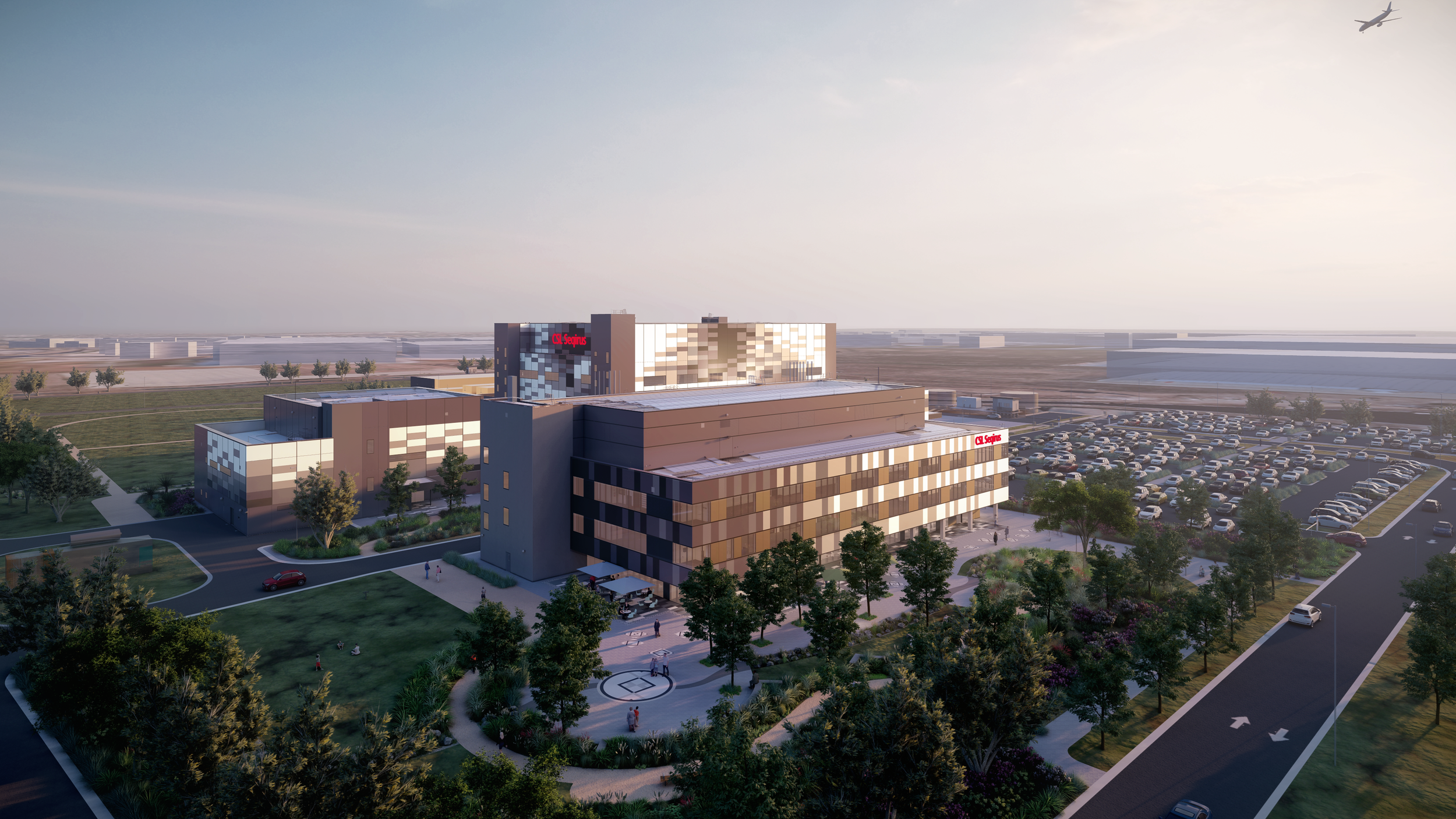

Stirlings is proud to have supplied a significant portion of the pharmaceutical standard Stainless steel for use in the construction of CSL Seqirus, a new state-of-the-art vaccine and anti-venom manufacturing facility in Tullamarine, Victoria!

The project is on schedule to be operational in 2026; and will be used for seasonal and pandemic cell-based influenza vaccine manufacturing, antivenoms, Q-Fever vaccine manufacturing, administration, and laboratories.

The project, by nature of both the application and needs of CSL Seqirus, demanded an accomplished and unwavering supply partner – Stirling’s extensive experience in sourcing, packaging and logistics management for blue chip projects around Australia was put to good use.

Stirlings supplied over 9,500 metres of Tube and more than 29,000 Fittings in ASME-BPE SF1 mechanical polish, ASME-BPE SF4 electropolish and AS1528 in Grades 316/L and 904L in sizes from ¼” to 8”.

ASME-BPE Pharmaceutical materials were sourced from multiple Stirlings strategic supply partners. Supplied to CSL Seqirus via 58 shipments, every part was diligently checked and recorded in our Hallam facility in Victoria. Additionally, Stirlings provided extensive documentation & control to ensure full material traceability.